Anti-Vortex Plates

Al-Safrik Steel specializes in the manufacturing of high-quality Anti-Vortex plates. Our engineers are precisely designing the equipment through the latest measuring techniques. Al-Safrik Steels install Anti-Vortex Plates exclusively in UAE, Dubai, Sharjah, and Abu Dhabi. We can customize our product according to our client’s mentioned specifications. Al-Safrik Steel uses premium quality stainless steel that makes the products durable for a long time. Feel free to contact our team for your desired product!

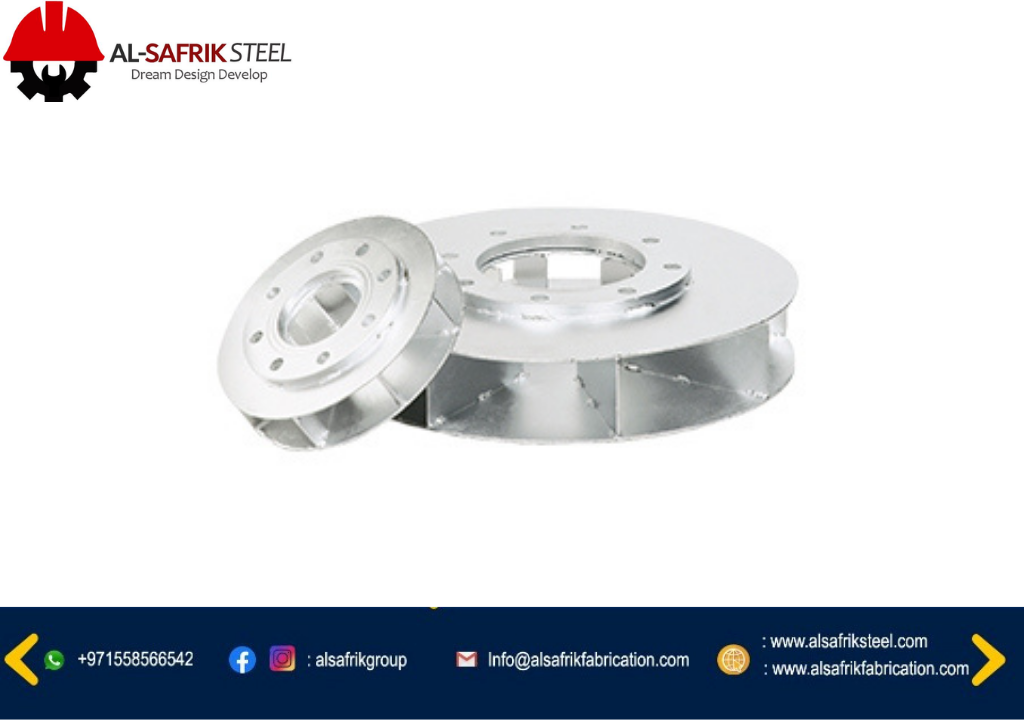

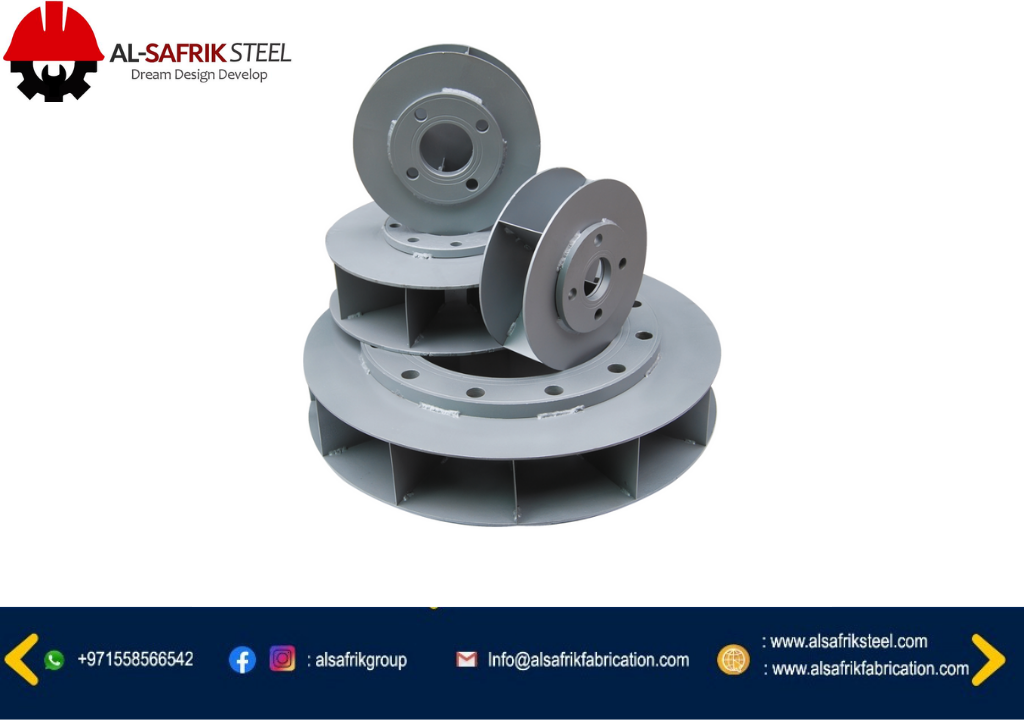

View Anti-Vortex Plates Gallery

What is Anti-Vortex Plate?

Anti-Vortex Plate is a vortex prevention device used to control the turbulence of fluid flowing in tanks. These Plates are placed in the suction line.

The function of Anti-Vortex Plates:

Vortices are generated when massive size pumps undergo suction from tanks. To avoid those vortices, anti-vortex plates are installed. It breaks the vortices and helps in the smooth flow of water.

Specifications:

Following are the prominent specifications of Al-Safrik Steel’s anti-vortex plates:

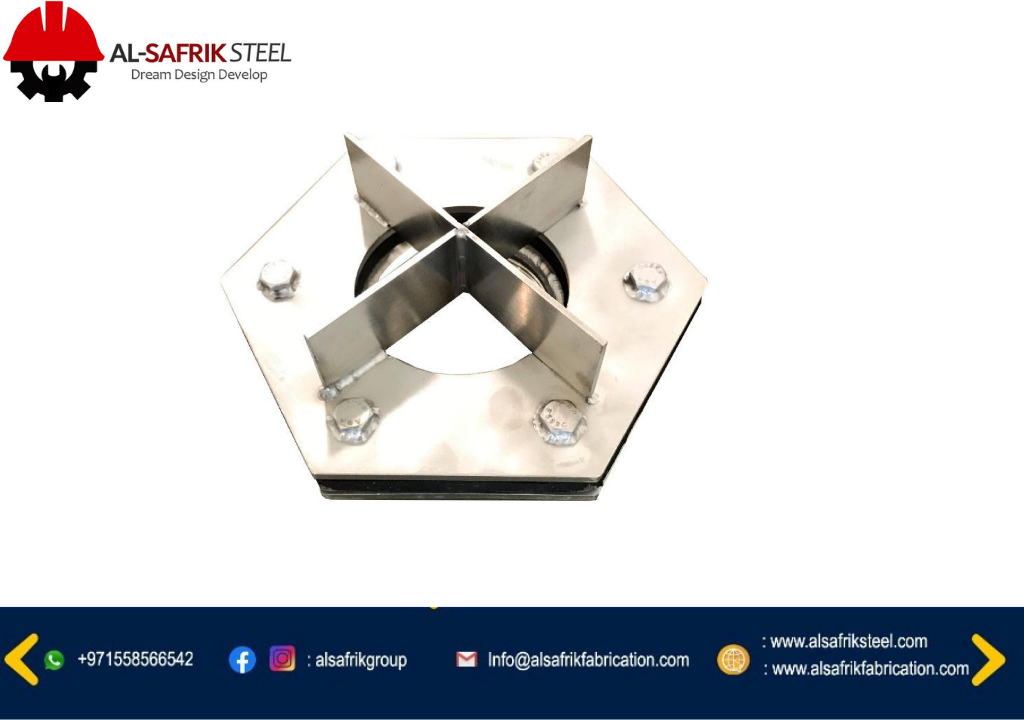

- Anti-vortex plates are manufactured using stainless steel and PVC.

- We manufacture Anti-vortex plates using stainless steel.

- Al-Safrik Steel’s Anti-vortex plates are manufactured using stainless steel in Grade 304 and 316L.

- Our engineer designs anti-vortex plates keeping suction size and NFPA standards in mind.

- We can also customize Anti-vortex plates according to our client’s requirements.

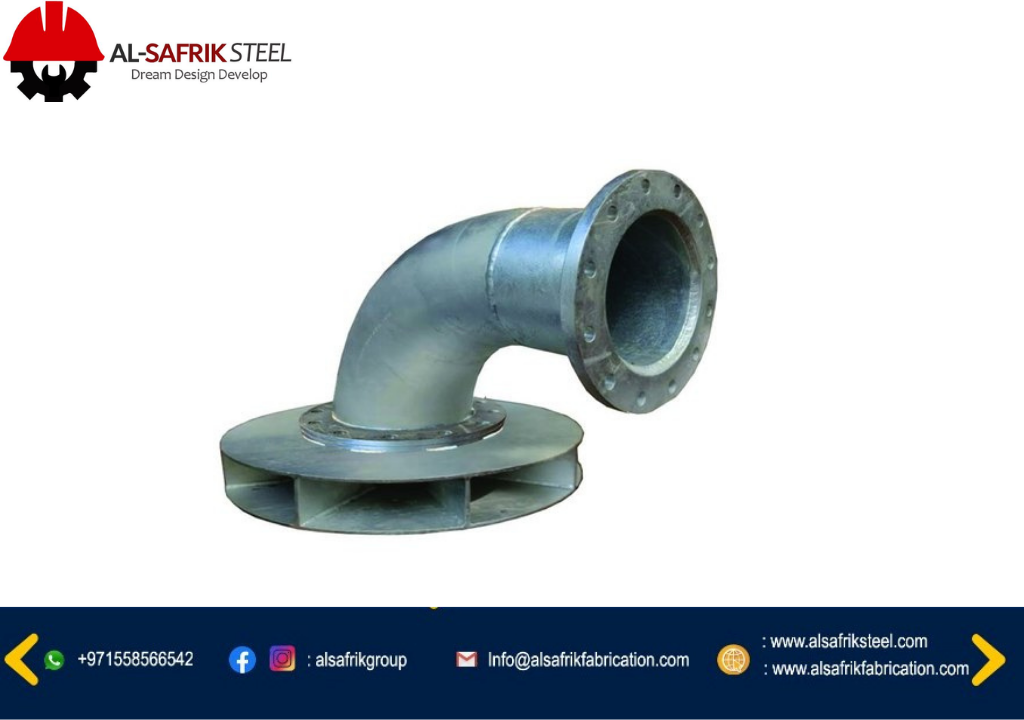

- According to NFPA standards, the assembly should have a horizontal steel plate that is at least double the diameter of the outlet on an extended radius elbow fitting. It must be arranged at the outlet a distance above the bottom of the tank equal to one-half the diameter of the discharge pipe.

- Installation dimensions should be the minimum distance above the bottom of the tank shall be 6 in. (152 mm).

Anti-vortex plate inspection:

The inspection of anti-vortex plates should meet all the requirements related to dimensions mentioned by NFPA.

Inspection should verify the installation of horizontal steel plates and long radius elbow.

After completing the construction of the tank and before filling the tank with water, all the necessary inspection procedures should be done.

What is Vortex?

A vortex is formed in a fluid when the flow rotates around an axis line in either a straight or curved direction. It is like a tornado created by fast-moving wind. Flow of fluid increases in a swirling motion at a high velocity. The turbulent flow of the fluid is controlled to prevent machine failure. Vortex created can also damage the rotating parts of the machine.

Why are Anti-vortex plates Important?

Anti-vortex plates help to minimize the vortex created. These plates decrease the speed of the fluid. The turbulent flow of fluid is converted into laminar flow. Anti-vortex plates smoothen the flow of fluid preventing cavitation. Cavitations are the free spaces created like bubbles or voids.

These cavitations can cause wear and tear of the machine. The cavitation produced can also cause damage like dents, imbalance, and shockwaves in the moving parts. Furthermore, the surface of the machine is eroded due to cavitation causing stress corrosion.

Corrosion due to cavitation occurs when the operating pressure is dropped below the fluid’s vapor pressure, causing the formation of gas bubbles that collapse at an increased velocity on the material’s surface, inducing initial cavitation.

Advantages of Anti-Vortex Plate:

The following points give us an idea about the advantages of Anti-Vortex Plates:

- Anti-Vortex plates are simple in design.

- These plates can be very easily installed and assembled.

- Anti-vortex plates are durable and have a long life.

- The cost of the plates is economical.

- These plates can constructively control the velocity of the fluid.

- Anti Vortex Plates help to reduce the velocity of a fast-moving fluid.

- The plates smoothen the fluid flow into a laminar drift instead of a turbulent flow.

- Anti-Vortex plate prevents the swirling of the water during suction, thereby ensuring unrestricted water flow.

- These plates help to decrease the wear and tear of the machine.

- Anti-vortex plates minimize the chances of cavitation corrosion.

- These plates help to control the velocity of the fluid.