The industrial sector of the UAE is advancing rapidly, with automation and efficiency becoming the driving forces. Whether it’s logistics, construction, or manufacturing, conveyor belts have become the backbone of material handling. However, the rapid advancements in the industry have completely evolved how conveyor belt systems operate. This blog takes a deeper look at how you can incorporate conveyor belts in your business to maximize efficiency. Read till the end to find out everything there is to know about top trends in the UAE industry and how you can benefit from them.

What is a Conveyor Belt?

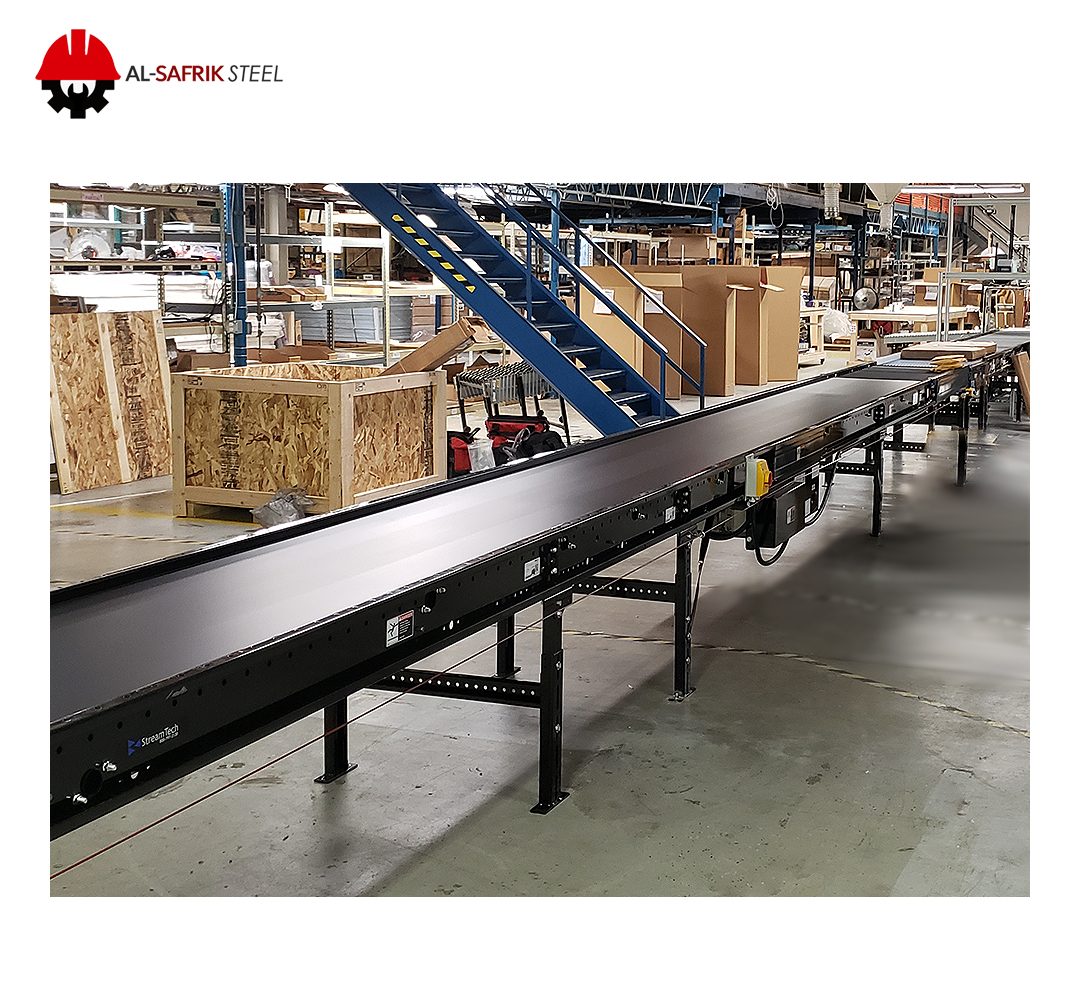

Facilities that have a continuous influx of goods need an automatic system to transport them effectively. Since transporting them by hand requires a lot of labour, a cost-effective solution was created in the form of conveyor belts. A conveyor belt is made of rubber and metal, and it runs continuously from one point to another. Goods can be placed on it for easy transportation. The belts are run with the help of motors, which eliminates the need for human intervention to transport the goods.

What are the major types of Conveyor Belts?

There are different industries that make use of conveyor belt systems. However, each may differ in the way they work and operate. Some of the major types of conveyor belts are as follows:

Roller conveyors:

These conveyors make use of a series of axles to facilitate the movement of goods. They can either be powered or operate on gravity if placed on an incline. Roller conveyors are often used in warehouses, production lines, etc., as they provide smooth material movement. However, you may be limited to specific item shapes and sizes, so we recommend checking with your load prior to getting these conveyors installed.

Screw conveyors:

Screw conveyors differ mainly in construction from roller conveyors. They use a steel auger and a helical screw that moves the items along the conveyor path. Their compact design makes them ideal for areas where space is an issue. However, the heavy duty screw blade is great for moving bulky materials. These conveyor belts can be spotted in agriculture and food industries, where the average load is much heavier. Screw conveyors are a great tool and can be safely used in vertical, horizontal or inclined settings.

Belt conveyors:

These conveyors work on a continuous belt system that moves between two pulleys. A motor is used to move the belt, and a metal slider pan is used to manage the weight. Belts come in various materials such as leather, fabric, plastic, or rubber, which can be selected based on the requirements. However, rubber is a much safer option and is generally used in the industry as a go-to option. The conveyor belt system can be used for long distances; however, it is advised not to subject it to heavy loads.

Gravity conveyors:

Gravity conveyors are a non-powered variant of conveyor systems, suitable for inclined planes. They can also be used in the absence of electricity, making them a truly versatile tool. They are ideal for medium to light-weight loads and can prove to be a workhorse in high-functioning environments. Although they are highly economical and environmentally friendly, they require inclined planes to function.

Pneumatic conveyors:

Pneumatic conveyors depend on high air pressure to move materials through the pipeline. Instead of mechanical rollers, they solely rely on compressed air within a system of sealed pipes. The positive pressure pushes the materials, whereas vacuum is used to pull them. This ingenious way of transporting materials is ideal for transporting low to medium loads such as fine powders, cement, etc.

Industrial rollers:

Industrial rollers, as the name suggests, are bulky and highly durable. They are made from strong materials that allow them to transport heavy materials. As they are powered by a motor, they are suitable for straight as well as inclined planes. These conveyors can be easily spotted at construction sites, manufacturing facilities where the expected load is much heavier.

What specifications do conveyor belt systems come in?

When looking for a conveyor belt system, you should consider some technical aspects. These will help you in choosing the right system for your business. Here are some crucial specifications you should look for when buying a conveyor system;

Load capacity:

Load capacity refers to the amount of load a conveyor system can handle. The higher the number, the better the load-bearing capacity. However, oftentimes people tend to ignore systems that are an overkill for their use case. We recommend calculating the average load as well as the maximum load your business handles. This will help you determine your requirement and potentially save some money, which can be spent elsewhere.

Rated speed:

Rated speed refers to the speed at which the conveyor moves. This can differ from system to system. If your business needs to move goods rapidly, we suggest investing in a high-quality conveyor system with good speed. Since this can directly affect the efficiency of your business, it is crucial to correctly identify your required speed.

Belt material:

Conveyor belts come in various materials. You can choose from a wide range of materials such as leather, rubber, plastic, or fabric. Although all materials are durable, we recommend choosing either leather or rubber, as they tend to last longer.

Ease of maintenance:

Conveyor systems tend to require maintenance at regular intervals, which is why easy maintenance is a must. Al Safrik Steel manufactures highly durable systems that are extremely easy to maintain and tend to last longer. You can consult our online support to find out about the expected life of each conveyor system.

Top trends in conveyor belt systems

Just like any other product, conveyor belt systems are also evolving. Here are the top trends you should keep an eye on in 2025:

1. Robotic Integration:

Conveyor belts are no longer stand-alone systems. Many industries in the UAE are integrating conveyor belts with robotic arms and automatic loading/unloading stations. This reduces human error and speeds up processes. These integrated systems are especially helpful in e-commerce warehouses, FMCG packaging plants, and large-scale distribution centers. By working in tandem, robots and conveyors make for a faster and more accurate operation.

2. Hygienic conveyor belts:

The food and pharmaceutical industries in the UAE are booming, and with it, the demand for hygienic conveyor belt systems has grown tremendously. Belts made from FDA-approved materials with easy-to-clean surfaces are now the standard. These belts reduce contamination risks and meet the strict hygiene protocols of the sector. With the rise in health consciousness and global safety standards, clean conveyors are more important than ever.

3. Heat and corrosion-resistant materials:

Given the UAE’s intense climate and industrial environment, durability is key. That’s why many companies are now investing in conveyor belts made from heat-resistant, corrosion-resistant, and anti-abrasive materials. Whether transporting materials in the scorching outdoors or dealing with corrosive chemicals, modern belts are built to survive harsh conditions. This is especially relevant for sectors like cement, steel, and chemical manufacturing.

4. IOT Integration:

Conveyor belts are now getting smarter with the help of IoT (Internet of Things). Sensors are installed on the belt systems to monitor real-time data such as load weight, temperature, alignment, and belt speed. This allows for predictive maintenance, minimizing downtimes and saving industries from unexpected shutdowns. Smart belts alert the operator before failure occurs, increasing the lifespan of the entire system.

Which industries can benefit from conveyor belt systems?

Multiple industries can benefit from conveyor belt systems. The possibilities of automating tasks are endless. Here are the following industries that can benefit from conveyor systems:

- Manufacturing and assembly line

- Food and beverage processing

- Mining and quarrying

- Logistics and warehousing

- Construction

- Airport baggage handling

- Recycling and waste management

Frequently Asked Questions (FAQs)

Here are some of the most frequently asked questions on your website.

1. Are conveyor belts suitable for heavy materials?

Yes. Conveyor belt systems come in various sizes. Our systems are made from high-quality steel, which is highly durable and suitable for heavy materials.

2. Can conveyor belts be customized for my facility?

Yes. Al Safrik Steel has the ability to manufacture custom steel products. We have in-house facilities to manufacture customized conveyor systems that are suited to your needs.

3. Is it possible to automate conveyor systems?

Yes. Conveyor systems can be integrated with automated sensors, which can reduce errors and help bring down operational costs.

Why Al Safrik Steel is your go-to partner in the UAE?

Al Safrik Steel is a premium steel manufacturer in the UAE. Our operations are not limited to the UAE but also spread to Saudi Arabia, proving our excellence. We use high-quality steel, which is optimized for the UAE atmosphere. Whether you use our products inside or outside, you need not worry. The high tensile strength steel will ensure longevity and high durability.

Al Safrik Steel has a wide range of products to choose from. We have high-quality conveyor belt systems that are suitable for all use cases. Additionally, we also have industrial steel products that are optimized for a wide range of use cases. So, no need to look further. Visit our website today and find the product that fulfills your needs.